A wet wire drawing machine is a specialized industrial equipment used to reduce the diameter of metal wires through a drawing process that uses a liquid lubricant or coolant. Unlike dry wire drawing, the wet process ensu...

READ MORE-

-

Straight line wire drawing machines are essential equipment in the metalworking industry, designed to reduce the diameter of metal wires while improving surface finish and tensile strength. These machines are widely used...

READ MORE -

Auto wire pay-off machines are essential equipment in modern wire processing facilities. They are designed to hold and unwind wire coils automatically, ensuring consistent tension and smooth feeding into downstream machi...

READ MORE

Pingsheng’s Wet Wire Drawing Machine: Reliable, Efficient, and Easy to Operate

Wuxi Pingsheng Science & Technology Co., Ltd. is a leading manufacturer of advanced wire drawing machines and auxiliary equipment, with decades of experience in the industry. Among its offerings, Pingsheng’s wet wire drawing machines stand out for their reliability, efficiency, and ease of operation.

Wet wire drawing machine is crucial for producing various types of metal wire, such as carbon steel, galvanized steel, stainless steel, and copper wire. These machines use a wet process that involves cooling and lubricating the wire and drawing dies, improving both efficiency and product quality. Pingsheng offers several configurations, including heavy, medium, light, turnover, and shaft types, to meet the needs of different industries like manufacturing, construction, and automotive.

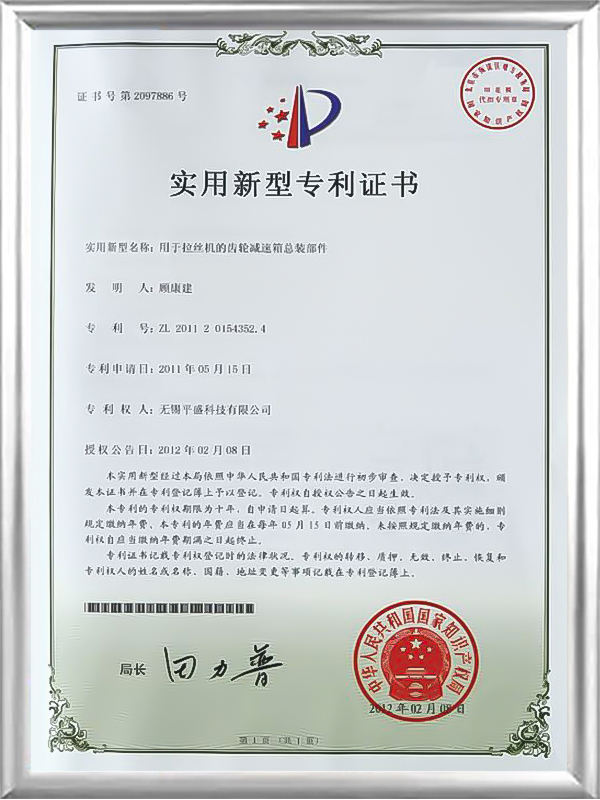

What sets Pingsheng apart is its commitment to innovation. The company has developed numerous patented components, such as the inlet die box, four-axis device, spray cooling system, and straightening mechanism. These features enhance the machine's performance and reliability, ensuring smooth operation with minimal downtime.

A standout feature of Pingsheng’s wet wire drawing machines is their advanced cooling and lubrication system. This system cools the metal wire and drawing dies while properly lubricating them, extending the lifespan of the drawing tools and ensuring consistent, high-quality results. The machine also ensures optimal diameter reduction and wire guidance at each pass.

Additionally, Pingsheng’s machines are designed for ease of operation. The user-friendly control systems make it easy for operators to manage the drawing process, enhancing precision and reducing errors. This combination of simple operation and robust performance makes Pingsheng’s wet wire drawing machines a reliable, cost-effective choice for businesses looking to improve production efficiency.

Pingsheng is committed to not only providing top-quality machines but also offering comprehensive after-sales support, earning the trust of industries both domestically and internationally. With its continuous innovation and focus on customer satisfaction, Pingsheng remains a leader in the wire drawing machine industry.

Pingsheng’s Wet Wire Drawing Machine: Reliable, Efficient, and Easy to Operate

Wuxi Pingsheng Science & Technology Co., Ltd. is a leading manufacturer of advanced wire drawing machines and auxiliary equipment, with decades of experience in the industry. Among its offerings, Pingsheng’s wet wire drawing machines stand out for their reliability, efficiency, and ease of operation.

Wet wire drawing machines is crucial for producing various types of metal wire, such as carbon steel, galvanized steel, stainless steel, and copper wire. These machines use a wet process that involves cooling and lubricating the wire and drawing dies, improving both efficiency and product quality. Pingsheng offers several configurations, including heavy, medium, light, turnover, and shaft types, to meet the needs of different industries like manufacturing, construction, and automotive.

What sets Pingsheng apart is its commitment to innovation. The company has developed numerous patented components, such as the inlet die box, four-axis device, spray cooling system, and straightening mechanism. These features enhance the machine's performance and reliability, ensuring smooth operation with minimal downtime.

A standout feature of Pingsheng’s wet wire drawing machines is their advanced cooling and lubrication system. This system cools the metal wire and drawing dies while properly lubricating them, extending the lifespan of the drawing tools and ensuring consistent, high-quality results. The machine also ensures optimal diameter reduction and wire guidance at each pass.

Additionally, Pingsheng’s machines are designed for ease of operation. The user-friendly control systems make it easy for operators to manage the drawing process, enhancing precision and reducing errors. This combination of simple operation and robust performance makes Pingsheng’s wet wire drawing machines a reliable, cost-effective choice for businesses looking to improve production efficiency.

Pingsheng is committed to not only providing top-quality machines but also offering comprehensive after-sales support, earning the trust of industries both domestically and internationally. With its continuous innovation and focus on customer satisfaction, Pingsheng remains a leader in the wire drawing machine industry.

EN

EN

English

English Español

Español Français

Français Português

Português عربى

عربى