How does a wire drawing machine work? What are its important applications in industrial production?

In the field of metal processing, a wire drawing machine is a key equipment widely used in many industries such as wire and cable, building steel bars, and spring manufacturing. Its main function is to gradually reduce the diameter of thick-diameter metal wire through a die to obtain a thin metal wire with specific size and mechanical properties.

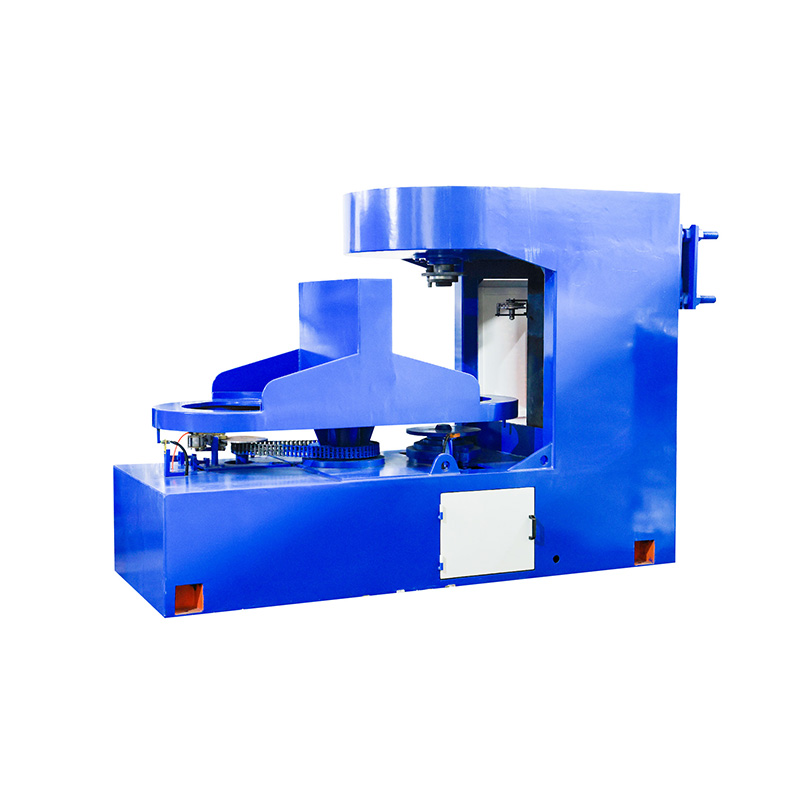

A wire drawing machine usually consists of the following core parts:

Wire-releasing device: used to provide the original wire and maintain a certain tension;

Wire drawing die holder: contains one or more wire drawing dies, which is a key component for achieving wire diameter reduction;

Drawing system: a driving device that allows the wire to pass through the die through traction;

Wire-receiving device: used to collect the finished wire after processing and control the winding tension;

Lubrication system: reduces friction and wear, prolongs the life of the die and improves the surface quality of the wire;

Control system: modern wire drawing machines are often equipped with automated control systems to achieve precise adjustment and monitoring of the production process.

The process of wire drawing is essentially a cold deformation process. The basic principle is to force the wire through a die hole with a smaller diameter than the original diameter through external force, so that the metal material undergoes plastic deformation, thereby achieving the purpose of reducing the diameter. In this process, the strength of the metal wire increases and the ductility decreases, so sometimes the intermediate annealing process is combined to restore the machinability of the material.

According to different operation methods, wire drawing machines can be divided into single drawing machines and multi-stage continuous drawing machines. The latter is more common in large-scale industrial production and can significantly improve production efficiency.

Wire and cable industry: used to produce conductor materials such as copper and aluminum to meet the needs of power transmission and communication;

Construction industry: manufacturing building materials such as steel bars and wire mesh;

Automobile industry: used for the production of high-strength wires such as spring steel wire and tire cord;

Electronic and electrical industry: fine metal wires are used for circuit connection and precision component manufacturing;

Aerospace: preparation of high-precision, high-performance alloy wires.

As the manufacturing industry develops towards intelligence and greening, wire drawing machines are also constantly upgrading. For example:

Introducing PLC and touch screen control systems to achieve human-machine interaction and automatic adjustment;

Adopting energy-saving motors and efficient lubrication systems to reduce energy consumption and environmental pollution;

Developing high-speed wire drawing technology and composite wire drawing units to improve production capacity and stability.

Wire drawing machines, as important equipment for metal processing, play an indispensable role in the modern industrial system. In the future, with the development of new materials and new technologies, their performance and application range will be further expanded.

EN

EN

English

English Español

Español Français

Français Português

Português عربى

عربى