How Do Multi Unit Wire Take-Up Machines Handle Different Wire Types and Sizes?

Wire take-up machines play a crucial role in the wire manufacturing, processing, and distribution industries. These machines are designed to collect, coil, and package wires efficiently after they have been drawn, insulated, or coated. Among these, multi unit wire take-up machines are particularly significant because they allow simultaneous handling of multiple wires, enhancing productivity, precision, and operational efficiency. One of the critical challenges in wire processing is dealing with the wide variety of wire types and sizes. This article explores how multi unit wire take-up machines manage these differences while maintaining high-quality output.

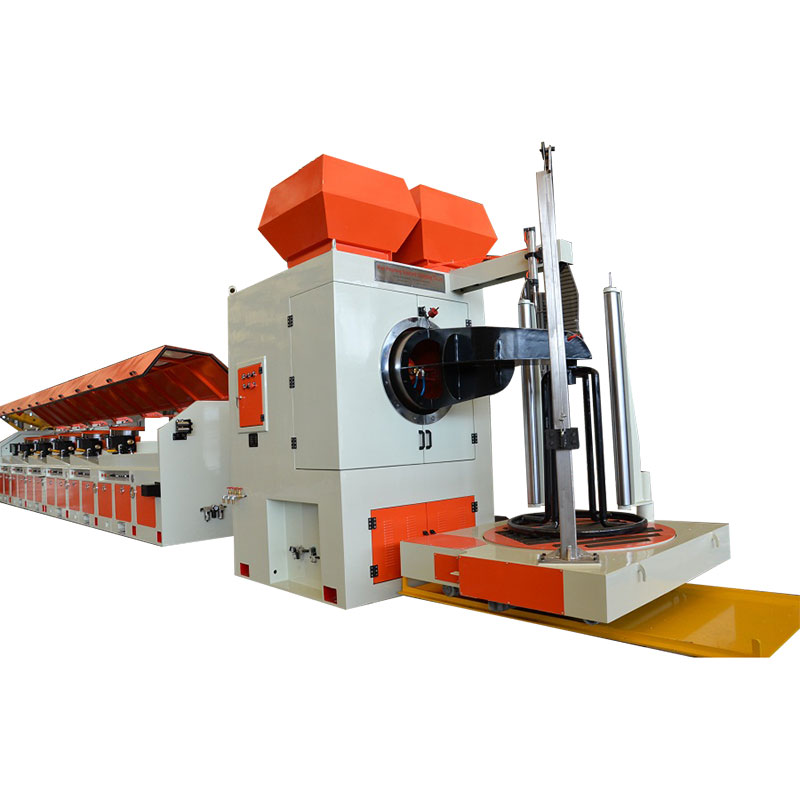

Understanding Multi Unit Wire Take-Up Machines

A multi unit wire take-up machine consists of several take-up units operating simultaneously on a single production line. Each unit is equipped with spools, tension control systems, and guiding mechanisms to ensure consistent coiling of wires. Unlike single-unit machines that handle one wire at a time, multi unit machines can process multiple wires of the same or different types concurrently. This is particularly useful in industries where high-volume wire production is required, such as electrical wiring, automotive cables, telecommunication lines, and industrial cabling systems.

These machines are designed to handle a variety of wire materials, including copper, aluminum, steel, and specialty alloy wires. They are also compatible with insulated and uninsulated wires, enamel-coated magnet wires, and high-temperature-resistant cables. The ability to adapt to different wire specifications makes multi unit take-up machines an indispensable part of modern wire processing lines.

Key Challenges in Handling Different Wire Types and Sizes

Wire manufacturing involves a wide range of wire diameters, material types, and surface finishes. Each variation presents unique challenges for a take-up machine. For instance:

Wire Diameter: Fine wires are prone to breakage and require gentle handling, while thicker wires demand higher tension and robust guiding systems.

Material Type: Soft copper wires can stretch or deform under tension, whereas harder aluminum or steel wires require stronger pulling and coiling mechanisms.

Insulation and Coating: Insulated wires need precise tension control to prevent damage to the insulation, while coated or magnet wires may require special surface-friendly rollers to avoid scratches or abrasions.

High-Speed Operation: Handling multiple wires simultaneously at high speeds increases the risk of tangling or overlapping if the machine is not correctly calibrated.

Addressing these challenges requires sophisticated engineering, advanced control systems, and adjustable components that can be tailored to each wire type and size.

Mechanisms for Handling Different Wire Types and Sizes

Multi unit wire take-up machines employ several mechanisms to accommodate diverse wire characteristics:

Adjustable Tension Control: Each unit in a multi unit machine has independent tension control systems. These systems can be set according to the wire material, diameter, and desired coil density. For delicate wires, tension is reduced to prevent stretching or breakage. For thicker or stronger wires, tension is increased to ensure proper winding. Modern machines use electronic tension controllers that automatically adjust in real-time, compensating for variations in wire feed speed and diameter.

Interchangeable Spools and Guides: The spool holders and wire guides in each unit are often interchangeable. Operators can change the spool size or guide rollers to suit the wire’s thickness and material. Smooth, low-friction rollers prevent damage to delicate insulation, while stronger guides are used for rigid wires. This modularity allows a single machine to handle multiple wire types without the need for separate equipment.

Programmable Control Systems: Advanced multi unit machines are equipped with programmable logic controllers (PLCs) or touch-screen interfaces. These systems allow operators to input specific wire parameters such as diameter, material, insulation type, and desired coil length. The machine automatically adjusts the speed, tension, and winding pattern for each wire, reducing manual intervention and human error.

Variable Speed Drives: Wires of different sizes and materials may require different winding speeds. Multi unit machines often feature variable frequency drives (VFDs) for precise speed control. Fine wires are wound at slower speeds to prevent tangling, while larger wires can be wound faster without compromising quality. This flexibility ensures uniform coil formation across different wire types.

Precision Alignment Systems: To handle multiple wires simultaneously, alignment systems prevent overlapping or tangling between adjacent wires. Laser guides or mechanical combs maintain proper spacing, ensuring each wire is wound neatly onto its spool. This is particularly important in multi-unit operations where slight misalignments can lead to production downtime or defective coils.

Automatic Fault Detection: Modern multi unit take-up machines incorporate sensors to detect breaks, tension fluctuations, or improper winding. These sensors automatically stop the affected unit, allowing operators to correct the issue without interrupting the entire production line. This feature ensures that wires of different types and sizes can be processed safely and efficiently.

Applications in Various Industries

Multi unit wire take-up machines are used across multiple industries where wires vary in type and size:

Electrical and Electronics Industry: Copper wires, magnet wires, and insulated electrical wires of varying diameters are wound simultaneously for consumer electronics, appliances, and industrial equipment.

Telecommunication Industry: Multi-core cables and fiber optic wires, which require precise tension and careful handling, are processed using multi unit take-up machines.

Automotive Industry: Automotive cables, such as power and signal wires, are produced in different gauges. Multi unit machines enable simultaneous winding, reducing production time.

Construction and Infrastructure: Aluminum and copper wires used for power distribution require careful coiling to prevent kinks and damage, which multi unit machines facilitate efficiently.

Industrial Manufacturing: Specialty alloy wires used in heating elements, instrumentation, and aerospace applications are handled with precise tension and alignment, ensuring consistency in quality.

Advantages of Multi Unit Wire Take-Up Machines

The ability to handle different wire types and sizes in a single production line offers several advantages:

Increased Productivity: Multiple wires are processed simultaneously, reducing downtime and increasing throughput.

Consistency in Quality: Independent control of tension, speed, and alignment ensures uniform coils across all wire types.

Flexibility: The same machine can adapt to different wire materials and diameters, reducing the need for multiple machines.

Reduced Material Waste: Precise tension and alignment reduce the risk of wire breakage, tangling, or damage, minimizing scrap.

Lower Operational Costs: Fewer machines and less manual handling reduce labor costs and energy consumption.

Maintenance and Best Practices

To ensure optimal performance, operators should follow specific maintenance and operational practices:

Regularly inspect tension control systems, rollers, and spool holders for wear and tear.

Clean guiding mechanisms and spools to prevent debris from damaging the wire surface.

Calibrate tension and speed settings for different wire types before production starts.

Train operators to recognize warning signs of improper winding or tension imbalance.

Keep software and control systems updated to ensure precise programming for different wire sizes and materials.

Conclusion

Multi unit wire take-up machines are essential in modern wire manufacturing for efficiently handling a wide variety of wire types and sizes. Through advanced tension control, programmable systems, precision alignment, and interchangeable components, these machines ensure high-quality winding and coiling while maintaining productivity and safety. By accommodating differences in wire diameter, material, insulation, and speed requirements, multi unit wire take-up machines provide flexibility and efficiency that single-unit machines cannot match.

Industries ranging from electrical and telecommunications to automotive and industrial manufacturing rely heavily on these machines for their production lines. Proper operation, maintenance, and configuration of multi unit wire take-up machines are key to achieving consistent quality, reducing material waste, and optimizing throughput. For manufacturers and operators seeking to improve efficiency while handling diverse wire types, investing in multi unit take-up machines is not just a choice—it is a strategic necessity.

EN

EN

English

English Español

Español Français

Français Português

Português عربى

عربى