Wire Surface Treatment Line Equipment: What Makes It Essential for Modern Wire Manufacturing?

In the fast-paced and precision-driven world of wire manufacturing, achieving high-quality, corrosion-resistant, and clean wire surfaces is vital. This is where Wire Surface Treatment Line Equipment comes into play. These sophisticated systems are designed to clean, descale, coat, or prepare wire surfaces before drawing, extrusion, or further processing. But what exactly are these machines, and why are they indispensable to the modern metal and cable industries?

What Is Wire Surface Treatment Line Equipment?

Wire surface treatment line equipment refers to a combination of machines and systems used to treat the outer surface of metal wires. Common processes include:

Mechanical descaling (using brushes or shot blasting)

Chemical cleaning (acid or alkaline baths)

Pickling and rinsing

Phosphating or coating (to reduce friction in further processing)

Drying and lubrication

These processes are arranged in continuous or semi-continuous lines to ensure uniform and efficient treatment of wire materials such as steel, copper, aluminum, or alloys.

Why Is Surface Treatment Important in Wire Production?

Wire drawing and other downstream processes demand clean and prepared surfaces. Poor surface quality can lead to:

Die wear or damage

Wire breakage

Poor adhesion in coatings or insulation

Final product failure in applications like electrical wiring or structural components

Therefore, a high-performance surface treatment line not only enhances wire quality but also improves productivity and reduces operational costs.

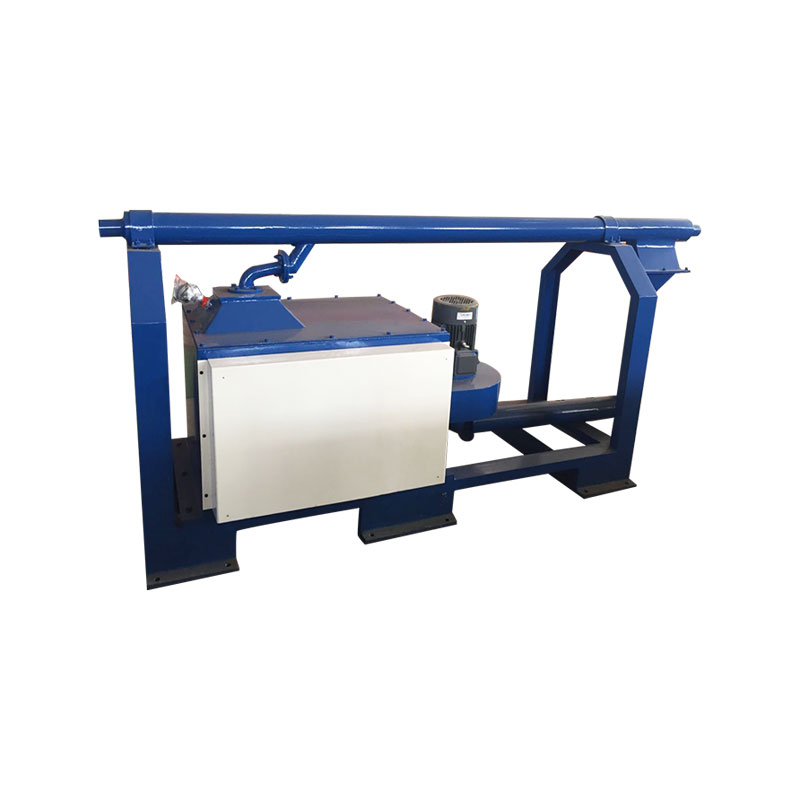

Key Components of a Wire Surface Treatment Line

Pay-Off and Take-Up Units: For uncoiling and recoiling the wire.

Mechanical Descalers: Remove rust or oxide layers using brushing wheels or shot blasting.

Pickling Tanks: Use acidic or alkaline solutions to chemically clean the surface.

Rinsing Units: Remove residual chemicals to prevent further corrosion.

Coating or Phosphating Units: Apply protective layers or lubricants.

Drying Chambers: Ensure the wire is moisture-free before coiling.

Fume Extraction and Filtration Systems: For environmental safety and operator health.

What Types of Wires Need Surface Treatment?

Almost all metal wires require surface treatment before further processing. These include:

Steel wires for construction, fasteners, or springs

Copper wires for electrical cables

Aluminum wires for power lines

Welded wire mesh and fencing wires

Each application demands specific surface properties, hence customization of the treatment line is often necessary.

How to Choose the Right Wire Surface Treatment Equipment?

When selecting surface treatment equipment, manufacturers should consider:

Material type (steel, copper, aluminum, etc.)

Wire diameter and production speed

Environmental regulations

Energy consumption and water usage

Integration with existing production lines

Leading suppliers often offer modular, customizable solutions that can scale with production growth.

Trends in Wire Surface Treatment Technology

Modern surface treatment lines are increasingly adopting:

Automation and digital controls for better process stability

Eco-friendly cleaning agents and closed-loop systems

High-efficiency heat exchangers in drying systems

Compact design to save floor space in factories

These innovations help reduce downtime, enhance worker safety, and meet stricter global environmental standards.

Common FAQs

Q1: Can surface treatment lines handle multiple wire types?Yes, advanced systems can be adjusted to accommodate different materials and diameters.

Q2: Are chemical treatments environmentally safe?Most modern systems are designed with recycling and neutralization systems to minimize environmental impact.

Q3: What is the maintenance requirement?Regular cleaning, inspection of chemical concentrations, and mechanical parts maintenance ensure optimal operation.

Q4: How long does a complete treatment cycle take?It depends on the wire speed and number of stages, but high-speed lines can process hundreds of meters per minute.

Conclusion

Wire surface treatment line equipment is no longer an optional upgrade—it’s a fundamental requirement for manufacturers aiming to produce top-quality, durable, and reliable wire products. As industries demand higher standards and faster production, investing in modern treatment lines ensures competitiveness, compliance, and consistent product performance.

EN

EN

English

English Español

Español Français

Français Português

Português عربى

عربى