What Are the Key Components and Working Principles of a Multi-Unit Wire Take-Up System?

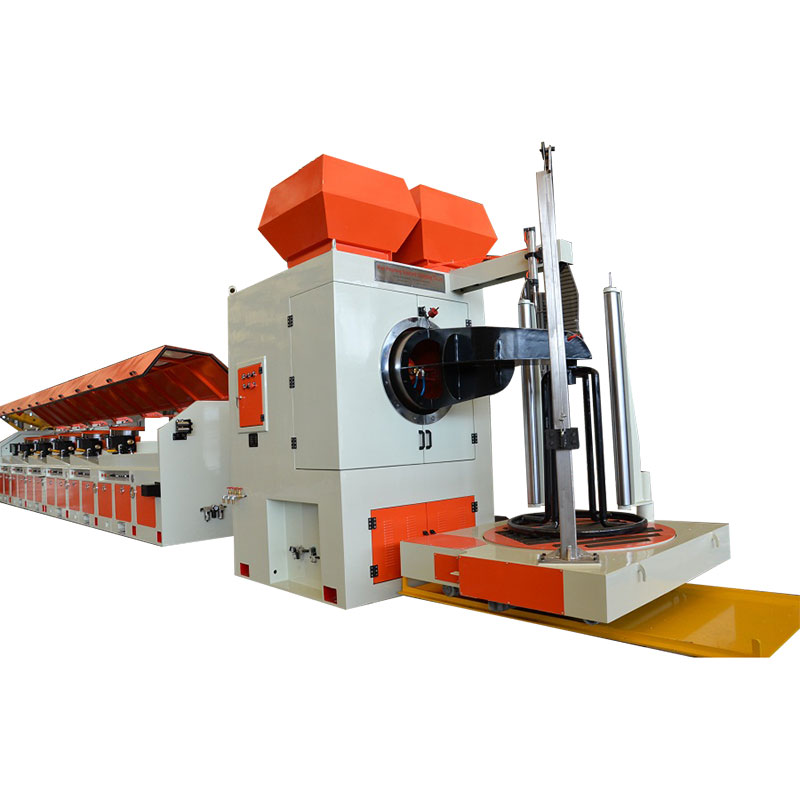

In the modern wire and cable manufacturing industry, multi-unit wire take-up systems play a crucial role in achieving high production efficiency, stable tension control, and precise winding quality. These systems are designed to automatically collect and wind finished wire or cable onto reels after processes such as drawing, annealing, or extrusion. Compared to single-unit take-up machines, multi-unit configurations allow for continuous, synchronized, and high-speed operation, significantly improving productivity and ensuring consistent output across multiple spools.

This article explores in detail the key components and working principles of a multi-unit wire take-up system, explaining how each part contributes to smooth operation, superior product quality, and optimized automation in industrial wire production.

1. Overview of Multi-Unit Wire Take-Up Systems

A multi-unit wire take-up system is an advanced mechanical setup consisting of multiple independent or semi-independent take-up stations arranged in parallel. Each unit is capable of operating simultaneously or in sequence, depending on the production line requirements. These systems are widely used in wire drawing, cable extrusion, enameled wire production, and fine wire processing.

Their main functions include:

- Reeling finished wire onto bobbins or spools with precise tension control.

- Maintaining constant line speed synchronization with upstream processes.

- Reducing downtime by allowing one unit to continue operating while others undergo spool changeover.

By integrating multiple take-up units, manufacturers achieve continuous production, greater flexibility, and enhanced product consistency, which are essential for large-scale wire and cable manufacturing.

2. Key Components of a Multi-Unit Wire Take-Up System

Each take-up station in a multi-unit system comprises several essential components that work together to perform controlled wire winding. The major parts include:

(1) Take-Up Spindle or Reel Holder

The spindle or reel holder is the core mechanical element that supports and rotates the wire reel. It is designed to accommodate various reel sizes, typically made of steel or aluminum, and is powered by an electric motor or servo drive.

In advanced systems, quick-change spindles or automatic clamping mechanisms are employed to reduce setup time and ensure efficient reel replacement.

(2) Drive Motor and Control System

Each unit typically includes an AC or servo motor controlled by a frequency inverter (VFD) or servo controller. This allows for precise control of rotational speed and torque, maintaining the correct wire tension.

Modern systems use digital control panels or PLC-based automation to synchronize the speed of all take-up units with the main production line, ensuring consistent winding even at variable line speeds.

(3) Tension Control Device

Tension control is critical for producing wire and cable of uniform quality. The tension control system can be mechanical, pneumatic, or electronic, depending on the machine’s design.

Electronic tension control systems use load cells, dancer arms, or feedback sensors to continuously monitor and adjust the motor torque, keeping the wire tension within precise limits. This ensures that the wire neither stretches nor slackens during take-up.

(4) Traversing Unit (Traverse Mechanism)

The traversing unit ensures the wire is evenly distributed across the reel width, forming a uniform and stable coil. This mechanism moves the wire guide back and forth in synchronization with the reel rotation.

The traverse motion can be cam-driven, servo-controlled, or ball-screw operated depending on the desired precision and line speed. Proper traverse coordination prevents wire overlapping, tangling, or uneven winding density.

(5) Wire Guiding and Alignment System

Before reaching the reel, the wire passes through guide rollers, pulleys, or ceramic eyelets that align and stabilize its position. These guides minimize vibration and ensure the wire enters the reel at the correct angle.

Some high-end machines feature automatic alignment correction systems, which detect deviations and adjust the guide path in real-time.

(6) Control Cabinet and Human-Machine Interface (HMI)

The control cabinet houses the electrical components, PLC, and motor drives, managing the system’s overall operation. The HMI touchscreen interface allows operators to monitor key parameters such as line speed, tension, reel diameter, and motor load.

Modern systems also offer data logging, remote monitoring, and fault diagnostics to enhance reliability and production efficiency.

(7) Safety and Protection Devices

To ensure safe operation, multi-unit take-up systems include emergency stop buttons, overload protection, safety guards, and limit switches that detect reel position or wire breakage. These safety measures protect both operators and equipment during high-speed operation.

3. Working Principles of a Multi-Unit Wire Take-Up System

The working principle of a multi-unit take-up system involves synchronized control of multiple reels winding wire simultaneously while maintaining stable tension and linear speed. The process generally follows these steps:

Step 1: Wire Entry and Tension Stabilization

After passing through the drawing or extrusion process, the wire enters the take-up unit through the tension control section. Sensors or dancer arms detect wire tension and send feedback signals to the motor controller, ensuring that the wire remains stable before winding begins.

Step 2: Reel Rotation and Speed Synchronization

Each reel’s motor begins to rotate, pulling the wire onto the reel at a controlled speed. The rotational speed automatically adjusts based on the reel’s increasing diameter to maintain constant linear winding speed. The system uses feedback loops between the main line controller and each take-up motor to ensure synchronization across all units.

Step 3: Traverse Motion for Layered Winding

As the reel rotates, the traverse mechanism moves the wire guide horizontally to distribute the wire evenly across the reel width. The traverse stroke, speed, and reversal timing are precisely matched to the reel’s diameter and wire thickness to achieve uniform layering.

Step 4: Diameter and Length Control

The system continuously monitors the reel diameter and wound length using encoders or sensors. When the desired reel size or length is reached, the system automatically slows down and stops the motor, ready for reel changeover.

Step 5: Automatic or Manual Reel Change

In continuous production systems, when one reel is full, another unit immediately starts winding without stopping the entire line. Some systems even feature automatic reel exchange, minimizing downtime and maximizing productivity.

4. Advantages of Multi-Unit Wire Take-Up Systems

The integration of multiple take-up stations provides several operational benefits:

- Continuous Operation: Enables reel changes without interrupting production.

- Higher Efficiency: Multiple units working in parallel significantly increase output.

- Improved Quality: Precise tension and traverse control ensure consistent wire quality.

- Automation-Friendly: Compatible with PLC control and industrial communication protocols.

- Reduced Downtime: Easy maintenance and reel replacement improve production uptime.

These advantages make multi-unit systems ideal for mass production of wires, cables, and conductors in industries such as electrical manufacturing, telecommunications, and automotive wiring.

5. Technological Trends in Modern Multi-Unit Take-Up Systems

As wire production becomes more automated, multi-unit take-up systems are evolving with advanced technologies:

- Servo-driven systems for precise speed and tension control.

- Intelligent PLC and IoT integration for real-time monitoring and predictive maintenance.

- Automatic reel loading and unloading to minimize manual handling.

- Energy-efficient designs using regenerative drives and optimized power control.

- Compact modular configurations for easier line integration and space-saving installation.

These innovations enhance productivity, reliability, and adaptability for modern manufacturing environments.

Conclusion

A multi-unit wire take-up system is an essential component of modern wire and cable production lines, combining mechanical precision, electronic control, and automation technology. Each of its core components—from the drive motor and tension controller to the traversing unit and HMI—plays a vital role in ensuring smooth, accurate, and continuous wire winding.

By understanding the key components and working principles, manufacturers can optimize system performance, minimize downtime, and achieve consistent product quality. As automation and digital control continue to advance, multi-unit wire take-up systems will remain at the heart of efficient, high-speed, and intelligent wire manufacturing operations.

EN

EN

English

English Español

Español Français

Français Português

Português عربى

عربى